Software (Carbon)

Open-source software from the Smarsly's group: Tools for the microstructure analysis of non-graphitic carbons

- OctCarb

-

Purpose of the software

OctCarb is a script for Octave that can be used to analyze and evaluate scattering data of non-graphitic carbons. The so-called non-graphitic carbons (NGCs) are an important class of sp2-based carbon materials that occurs a variety of natural and synthetic carbons used in industry and research (e.g. charcoal, activated carbon, glassy carbon, soot/carbon black, bituminous pitches). The bulk material can be used for various electrical and low-friction applications, while the porous derivatives are used, for example, in gas storage/separation. Non-graphitic carbon can also be used as electrodes for accumulators and supercapacitors. Carbons made from phenol-formaldehyde resins (PF-R), the so-called glassy carbons, serve as containers in high-temperature applications because of their high chemical resistance.

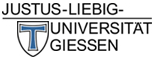

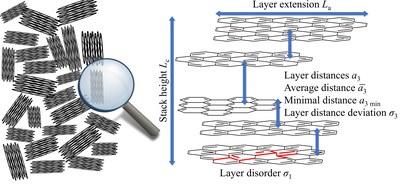

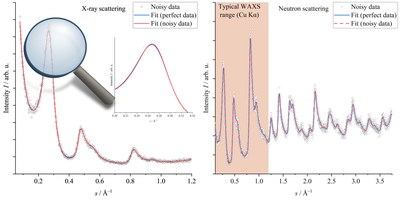

Physical properties such as thermal and chemical resistance as well as electrical characteristics are directly related to the microstructure of NGCs (Fig. 1: Stack extension and layer height (La and Lc) as well as their disorder (σ1 and σ3), the average and minimum layer spacing (a3 and a3 min) and the average C-C bond length (lcc)). However, the precise quantitative characterization of such substances is difficult: Electron microscopy (TEM, HRTEM) and Raman spectroscopy show only a small section of the sample. Therefore, wide-angle X-ray/neutron scattering (WAXS/WANS) is widely used to obtain quantitative structural parameters of NGCs. Due to the broad and overlapping reflections (Fig. 2), it is not possible to evaluate the scattering data with the usual methods. Therefore, special software is required for the analysis of such data. However, the currently available software for analyzing this data suffers from certain limitations.

Figure 1: Basic structure of non-graphitic carbons (NGCs):

NGCs consist of stacks of turbostratically arranged graphene layers (Adapted from Ref. 1).Figure 2: Exemplary wide-angle scattering data from NGCs:

Total scattering is a superposition of layer scattering, stacking scattering, and incoherent scattering (adapted from Ref. 1).For all applications, a quantitative determination of the microstructure based on experimentally accessible structural parameters is of crucial importance both for the coordination of production processes and for the linking of material properties with the microstructure. The latter includes macroscopic properties such as hardness, chemical stability or thermal and electrical conductivity and thus defines the final application. Obtaining these parameters is possible by evaluating the WAXS data from NGCs using an approach published in 2002 by Ruland & Smarsly[2]. With the help of the work of Pfaff, Badaczewski et al.[3, 4] a script (OctCarb) was developed which can be used for the freely available Octave software in order to automatically evaluate the scattering data and thus validly quantify the microstructure of NGCs.

Benefits and Application

The most important features are (not exhaustive):

- Completely free and open source for Windows, Mac and Linux

- Adjustment of various microstructure parameters such as:

- La and σ1 (average layer extent and disorder)

- Lc (average stack height)

- a3, a3 min and σ3 (average and minimum layer spacing and standard deviation (disorder)

- lcc (C-C bond length)

- Consideration of several correction terms and support of different X-ray wavelengths and measurement geometries

- Thinning factor for faster fitting curve calculation and autofitting, and the ability to omit beginning and ending points

- Different sizes for X-axis possible (θ, 2θ, s, q)

- Automatic output and storage of all parameters and adjustment graphs as text, table and image

- Data fitting for X-ray and neutron scattering possible

- Although the complex mathematical calculations are visible to the user, they do not have to be changed or taken into account manually

- Fully implemented mathematically known fit algorithm (Levenberg-Marquardt)

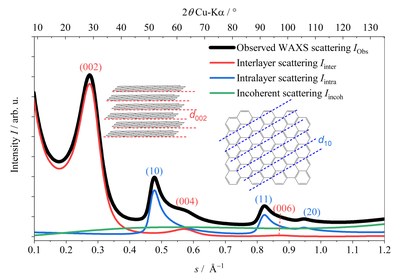

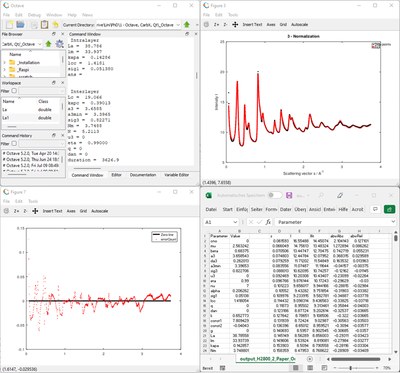

The Octave interface (Fig. 3) essentially consists of a script interface; the results (Fig. 4) are output as text, tables and images. All data is automatically saved on the hard disk.

Figure 3: Octave Main Graphical User Interface (GUI):

In the top bar, the Octave files (*.m) can be opened and saved and various windows can be activated and deactivated. The current working directory can be changed on the left-hand side and the currently used variables and executed commands are displayed there. In the lower pane you can toggle between the command window (user interface for the Octave command line), the editor (for editing the script files) and the variable editor and documentation (adapted from Ref. 1).Figure 4: WANS refinement results using the Octave script (OctCarb, top left):

In addition to the microstructural parameters in text form, categorized by stack and layer parameters, Octave shows the measurement data and the fit and deviation and saves everything in a CSV file and as images (Adapted from Ref. 1)Figure 5: Noise floor test with simulated WANS data noisy by random noise using a Gaussian distribution (σ = 0.05) (black):

The resulting fit of the noisy data (red) is very close to the simulated curve (blue). The noise level used corresponds to the typical noise of a real WANS experiment. The deviations between the original and refined structure parameters are very small, which means that such a noise level has no significant impact on the resulting calculated microstructure data. The data correspond approximately to a resin treated at intermediate heat treatment temperatures (1800 - 2500 °C) or a pitch at lower temperatures (1200 - 2000 °C) (Adapted from Ref. 1).More information, contact and download

The script (OctCarb) presented has been thoroughly tested and worked flawlessly. Nevertheless, the following disclaimer applies. The software is provided as is as open source software. Bug reports and suggestions are welcome (smarsly@uni-giessen.de or carbon).

The resulting script (OctCarb), instructions, videos, and more information were made available at https://github.com/osswaldo/NGCs.

An article about this software tool was published in the C - Journal of Carbon Researchy:

Osswald, O. & Smarsly, B. M. (2022). C. 8(4), 78

Disclaimer

This software is provided "as is" and any express or implied warranties, but not limited to the implied warranties of merchantability and fitness for a particular purpose are disclaimed. In no event shall the authors or copyright holders be liable for any direct, indirect, incidental, special, exemplary, or consequential damages (including, but not limited to, procurement of substitute goods or services; loss of use, data, or profits; or business interruption) however caused and on any theory of liability, whether in contract, strict liability, or tort (including negligence or otherwise) arising in any way out of the use of this software, even if advised of the possibility of such damages.

References

[1] Osswald, O. & Smarsly, B. M. (2022). C. 8(4), 78

[2] Ruland, W. & Smarsly, B. (2002). J. Appl. Cryst. 35, 624–633

[3] Pfaff, T. et al. (2018). J. Appl. Cryst. 51, 219-229

[4] Pfaff, T., Badaczewski, F. M. et al. (2019). J. Phys. Chem. C 123 (33), 20532–20546