State of the art and targeted innovation

- Figure: 1,2,3 Martin Becker. Figure 4: Elisa Monte

- State of the art and targeted innovation

-

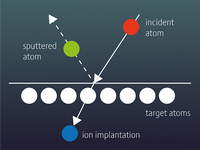

The deposition of thin layers and layer sequences can be done in various ways. This includes physical processes such as thermal or electron beam evaporation, cathode sputtering (conventional sputtering earthposition) or chemical processes are used. Subsequent post-treatments such as tempering, recrystallization, doping or targeted material removal with the help of chemical-mechanical polishing allow further layer optimization. The use of IBS as a coating technology offers many advantages over conventional processes, in particular the thermal and mechanical stress on the substrate is lower and the range of materials is broader.

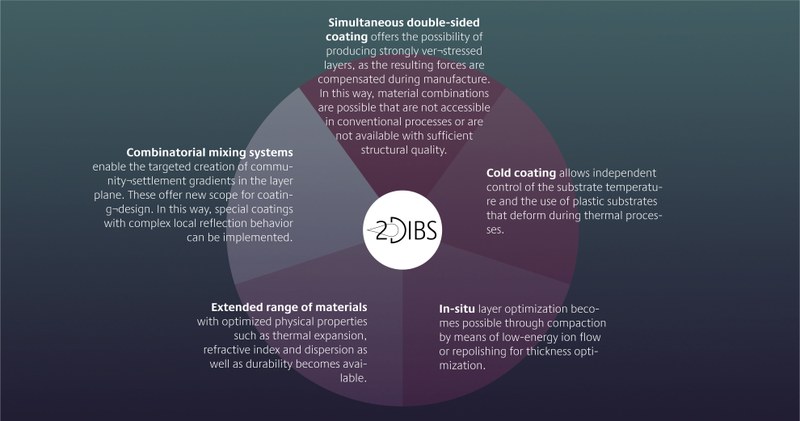

The 2DIBS development project aims at specific innovations and follow-up innovations:

- Simultaneous double-sided coating offers the possibility of producing strongly verstressed layers, as the resulting forces are compensated during manufacture. In this way, material combinations are possible that are not accessible in conventional processes or are not available with sufficient structural quality.

- Cold coating allows independent control of the substrate temperature and the use of plastic substrates that deform during thermal processes.

- In-situ layer optimization becomes possible through compaction by means of low-energy ion flow or repolishing for thickness optimization.

- Extended range of materials with optimized physical properties such as thermal expansion, refractive index and dispersion as well as durability becomes available.

- Combinatorial mixing systems enable the targeted creation of communitysettlement gradients in the layer plane. These offer new scope for coatingdesign. In this way, special coatings with complex local reflection behavior can be implemented.

The new process for the bilateral realization of complex multilayer layers with in-situ control is an innovative further development of existing technologies. It offers the industry new solution strategies for coatings that are currently not feasible.