High-Performance Materials for Next Generation Thermal Barrier Coatings in the System ZrO₂-HfO₂-Y₂O₃-Ta₂O₅

Research Associate: Alina Habermann

Thermal barrier coatings (TBCs) are widely used to protect hot components from high temperatures and aggressive conditions of gas turbines and diesel engines.[1] To ensure long-term protection, TBCs must meet the following properties: low thermal conductivity, phase stability at high temperatures, high compatibility with Al2O3, high fracture toughness and corrosion resistance.[2] Additionally, phase transformations in the applied temperature range should be avoided, because cracks can be formed that endanger the integrity of the protective layer.[1]

Yttria-stabilized zirconia is currently the material of choice for these high temperature applications. To circumvent phase transitions of the ZrO2 lattice from tetragonal to monoclinic during cooling, it is necessary to guarantee a high tetragonality of ZrO2 at high and low temperatures.[1] This can be accomplished by adding Y2O3 causing the formation of oxygen vacancies for charge compensation stabilizing the tetragonal distortion of the ZrO2 lattice.[1,3] Because of the resulting superior properties of 6-8 wt% yttria‑stabilized zirconia due to metastable phase formation, this is the consumption applied for TBCs.[2] To further increase the tetragonality of the ZrO2 lattice, doping with smaller cations or cations with higher oxidation states than Zr4+ (e.g. Ti4+, Nb5+, Ta5+) can be applied. Furthermore, the addition of Hf4+ should provide increased fracture toughness, phase and structural stabilities in the ZrO2 lattice at temperatures up to 1700 °C and generate low thermal conductivity above 1100 °C.[4] Thus, the ZrO2‑HfO2‑Y2O3‑Ta2O5 material system is of great interest for future TBCs due to high phase stability at high and low temperatures and low thermal conductivity (figure 1).

Figure 1: Development of different types of TBCs over decades (adapted from N. Padture, Nature Materials 2016).

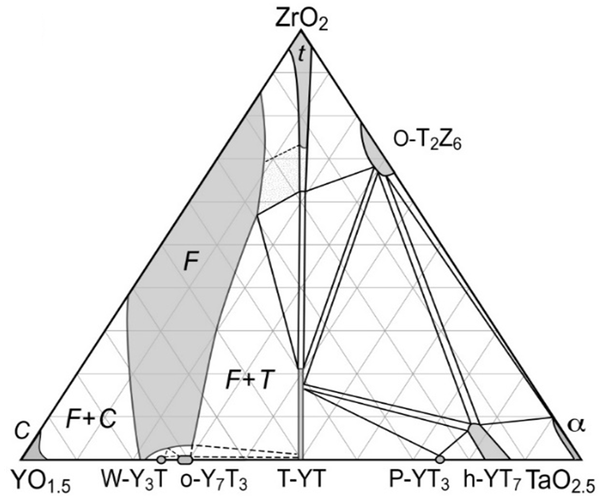

In this project, a systematic thermodynamic investigation in the ZrO2‑HfO2‑Y2O3‑Ta2O5 material system is performed in collaboration with TU Bergakademie Freiberg. Solid-state and precipitation reactions followed by calcination are used as syntheses routes. To obtain information on phase equilibria, thermochemical and thermophysical data as well as the different properties relevant for TBCs applications, characterization methods such as X-ray diffraction, scanning electron microscope, energy dispersive x-ray spectroscopy, differential scanning calorimetry, differential thermal analysis and laser flash measurements are performed. From the thermodynamic information and phase equilibria data a self-consistent database will be modeled using CALPHAD (CALculation of Phase Diagrams) method where phase diagrams (e.g., figure 2) can be calculated.

Figure 2: Quasi ternary phase diagram of the isothermal section for the ZrO2-YO1.5-TaO2.5 system at 1500 °C.[5]

References:

[1] Song, X.; Xie, M.; An, S.; Hao, X.; Mu, R. Structure and thermal properties of ZrO2-Ta2O5-Y2O3-LnO3 (Ln = Nd, Sm or Gd) ceramics for thermal barrier coatings. Scr. Mater. 2010, 62, 879-882.

[2] Limarga, A. Shian, S.; Leckie, R.; Levi, C.; Clarke, D. Thermal conductivity of single- and multi-phase compositions in the ZrO2-Y2O3-Ta2O5 system. J. Eur. Ceram. Soc. 2014, 34, 3085-3094.

[3] Li, P.; Chen, I.-W.; Penner-Hahn, J. Effect of Dopants on Zirconia Stabilization – An X‑ray Absorption Study: II, Tetravalent Dopants. J. Am. Ceram. Soc. 1994, 77, 1281-1288.

[4] Doronin, O.; Artemenko, P.; Stekhov, P.; Marakhovskii, P.; Stolyarova, V.; Vorozhtsov, V. Physicochemical Properties of Gd2O3-ZrO2-HfO2 Ceramics as Promising Thermal Barrier Coatings. Russ. J. Inorg. Chem. 2022, 67, 732-739.

[5] Macauley, C.; Fernandez, A.; Levi, C. Phase Equilibria in the ZrO2‑YO1.5‑TaO2.5 system at 1500 °C J. Eur. Ceram. Soc. 2017, 37, 4888-4901.

This Project is funded by Deutsche Forschungsgemeinschaft German Research Foundation (Projektnr.: 314579101).