Smart Materials and Intelligent System Design

- Smart materials and Intelligent System Design

-

Smart materials and Intelligent System Design

High vacuum, extreme temperatures, cosmic radiation and zero gravity–conditions in space are harsh and poses great challenges for material science. In addition to these rather well-known phenomena, space also leads to chemical challenges for space flight, such as those caused by atomic oxygen. Atomic oxygen is far more reactive than molecular oxygen, which is found on earth and is essential for breathing. In Low Earth orbit (LEO), atomic oxygen is the most abundant gas species and reacts with nearly every material. Therefore, it needs to be considered in almost every mission scenario into space.

In space flight, so-called polyimides are commonly used as heat shields or exterior coatings for spacecrafts. These polyimides are also found in day-to-day applications, such as in electric insulators or adhesive tapes. Despite considerable scientific effort to improve the material, polyimides still decompose when exposed to atomic oxygen.

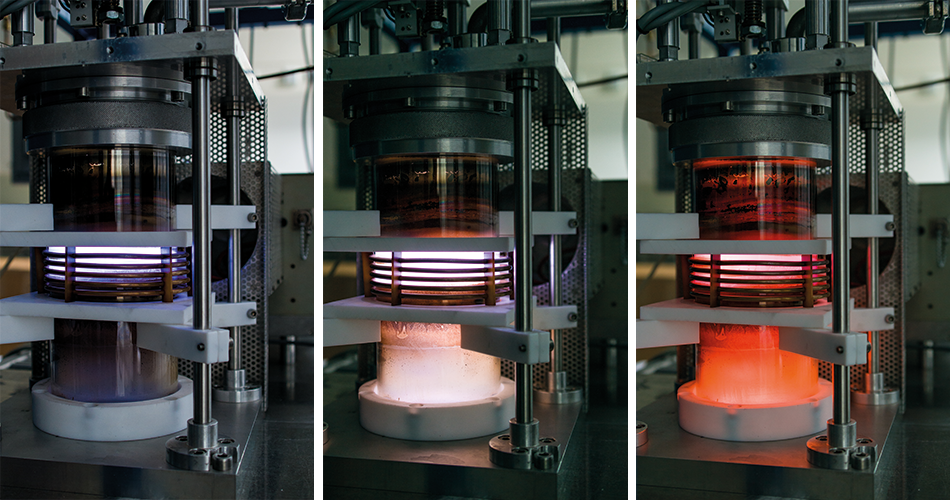

In order to understand the internal destruction of polyimides, the diffusion, i.e. the migration, of atomic oxygen within a polyimide will be studied in the innovation laboratory "Rough-ambient Physics", which is financially supported by the European Regional Development Fund (ERDF). The photograph depicts a self-built radio-frequency plasma apparatus in which materials are tested under space conditions. The reactive conditions in the luminous gas discharge are similar to those in LEO and serve to simulate and subsequently study the exposure of polyimides to this kind of space environment.

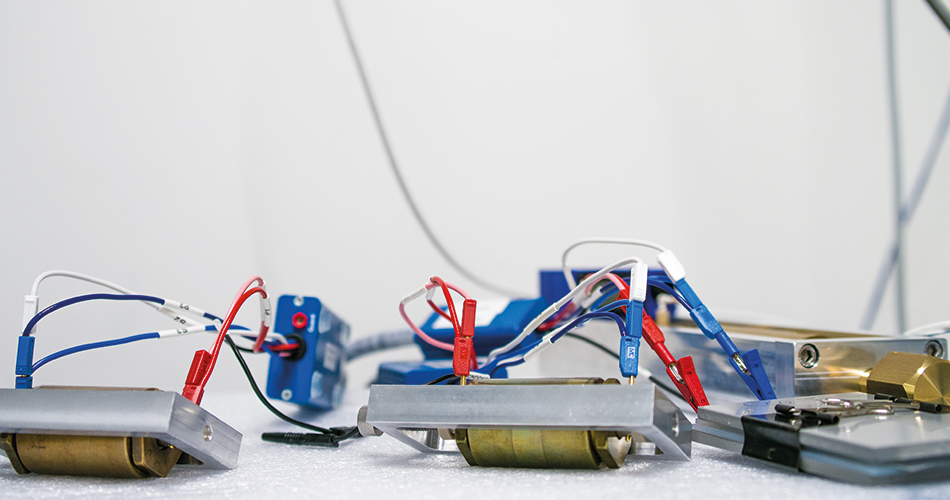

The intermediate storage of photovoltaic energy in batteries is of particular importance for maintaining reliable energy supply on spacecrafts. A central question, especially for longer space flights, is to what extent the hard radiation occurring in space will harm the electrodes and electrolyte materials used in these batteries.

In order to address this question, selected battery types are first electrochemically characterised in a so-called "Cycler". The batteries are then irradiated in test laboratories set up specifically for this purpose within the framework of this ERDF project. Finally, the batteries are electrochemically characterised again and examined by modern methods of materials science analytics in order to trace potential decomposition products. Based on these findings, improved, more radiation-resistant materials will be proposed.