Gallery of Pictures from 2015

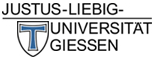

The picture shows a SEM-image of an undoped ceria (CeO2) thin film deposited by pulsed laser deposition (PLD) on a single crystalline sapphire substrate. The sample was kept at 1500 °C for overall 20 hours and afterwards coated with a thin layer of carbon to improve its electrical conductivity. The SEM image was taken at a specimen tilt of 70°. It shows the de-wetting of the previously area-covering CeO2 layer caused by the high-temperature treatment. This behavior is of interest for the investigation of the influence of morphology on the conductivity of ceria. (Picture submitted by Raika Oppermann.)

Structural phase transitions (reversible or irreversible) can be proved via temperature dependent x-ray diffraction. Two systems of Anton Paar enables the research group of Prof Janek to study powder as well as thin film samples under almost inert conditions. In addition, a special setup makes electrochemically induced structural changes accessible.The available diffractometers by PANalytical and respective heating chambers are shown in figure A) and B).At approximately 125 °C, Cu2Se undergoes a reversible phase transition of monoclinic to cubic structure. This is illustrated in figure C) by a reduced number of Bragg peaks at higher temperatures.(Picture submitted by Christian Schneider.)

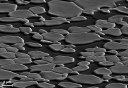

Within the Transregional Collaborative Research Centre SFB / TRR 79 new titanium-based implant materials with a remarkably low elastic modulus were fabricated at the Leibnitz Institute for Solid State and Materials Research Dresden for the treatment of osteoporotic bone fractures. Besides that a high tensile strength is required for load-bearing implant applications which can be achieved by reduction of the alloy grain size.With electron backscatter diffraction (EBSD) it is possible, to display the grain size and texture on a polycrystalline titanium-niobium-indium alloy (figure A, created by Arne Helth, IFW Dresden) based on the inverse pole figure. Figure B displays the topography of the surface after anodic oxidation in oxygen plasma at the same position which is marked by three indentations (white area). The image was acquired by white light interferometry (Sensofar group). By further examination it is clear that the oxide growth rate depends on the orientation of the underlying grain. (Picture submitted by Markus Göttlicher.)

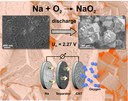

Rechargeable metal–air (or more precisely metal–oxygen) batteries with aprotic electrolytes are very attractive energy stores as they potentially combine low-cost components and very high energy densities. The reality of this type of battery, however, is complex and fundamental issues still need to be overcome in order to make any application feasible. The lithium–oxygen battery clearly is the frontrunner in recent worldwide research efforts, but recently it was found that replacing lithium by sodium can enable a much more controlled cell reaction by forming sodium superoxide during discharging. In a joint study from the Justus-Liebig-University Gießen and BASF SE, Conrad L. Bender et al. show that the capacity and cycle life of the sodium–oxygen battery can be improved by using technically processed, free-standing electrodes based on commercial carbon nanotubes. Deep discharging delivers a capacity of 1530 mAh/g for a few cycles, but a lifetime of more than 140 cycles is observed for shallow cycling. The results are superior in comparison to earlier studies on conventional carbon electrodes. The picture of the month shows the cell design and images of the carbon nanotube electrode before and after discharge. The discharge product (NaO2) crystallizes in the form of large cubic particles. More information can be found in the recently published work: http://onlinelibrary.wiley.com/doi/10.1002/ente.201402208/abstract(Picture submitted by Conrad L. Bender.)

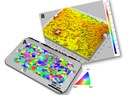

XPS (X-ray Photoelectron Spectroscopy) and ToF–SIMS (Time of Flight – Secondary Ion Mass Spectrometry) are complementary techniques to examine the surface available in the RG Janek. The figure shows the spatial distribution of the elemental concentrations (100 µm x 100 µm x ~10 nm) observed via SIMS and the according XPS detail spectra of those elements. As it can be seen a lithium sulfide layer (bottom left) is formed on top of a lithium substrate (top left). At the interface sulfur is bonded to oxygen (top right) originating from reaction of sulfur with the native oxygen layer of the lithium substrate. The whole layer system together with the phase composition, calculated out of the XPS spectra, is depicted at the bottom right. Since the analyzing depth of XPS is about 10 nm the thickness of the sulfur layer can be expected to be a few nanometers because of the high lithium metal content in the Li1s XPS spectrum. (Picture submitted by Hauke Metelmann)

The chemical institutes are moving to the new building. Therefore a new picture will not be available before November!